Crusher

Recycle Plastic Waste to Make Profit

General-purpose plastic crusher, which can crush both hard and soft materials

1. “V” shape knife holder structure

2. It can crush both hard and soft materials

3. Optional range of screen mesh: 6-100mm

4. It can be used alone or on the plastic cleaning line

5. Front knife holder and rear knife holder are optional

APPLICABLE MATERIALS

BRIEF DESCRIPTION

According to requirement of recycling production, our company developed PC series waste plastic crusher it is widely used in Polystyrene, Polypropylene, Nylon, Engineering plastics and waste Polyvinyl Chloride foamed material or injection lump crushing If replace the screen sieve, and adjust the blade clearance, it can also crush all kinds of blown film, rolling film, sheet, plate and other plastic waste.

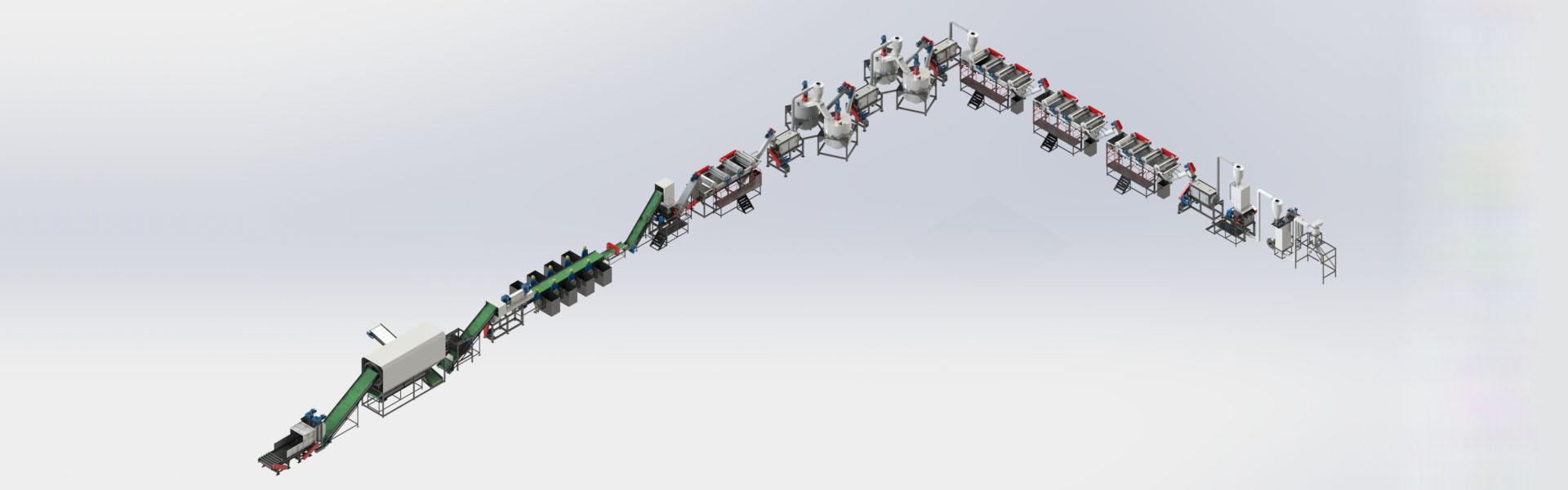

WORKING PROCESS

1. Adopt imported high quality tool steel for specially blades. Extremely wear-resisting, blades can be elastically fixed, repeatedly sharpened when blunt and achieve using life.

2. The Base of Rotary blade designs as step and scissors, so that the cutting force can be decomposed and caused double increase

3. Material of rotary blade base is T7A high-quality tool steel, rigid and flexible, which has stronger and long life. It adopts high intension bolts (12.9 level) to fix, the structure is solid and durable.

4. Machine body is made by advanced Q235A steel, which can avoid influence to mechanical properties after long time running.

5.Main Axis Core and both end face is finished by the high precision coordinate boring in one time, ensures concentricity and perpendicularity errors less than 0.05mm. Each of the components sets basic hole and surface with both coarse and fine processing. Parts are interchangeable and with high precision.

UNIT INTRODUCTION

The blades much wider, it can sharpen 20-25 times, it will save the blade cost

Rotor:With strong rotor made and shaft. Shaft made by 45#steel with quenching treatment

Chamber opened by screw motor. Motor power:0.75KW. Motor: All Copper Design: Smooth output, Strong Power. Radiator Hood: Make the motor performance good and can be used for a long time. High Hardness Shaft: Seiko manufacturing, more durable.

Electric Box: Install overload protection, use safer and more assured

TECHNICAL DATA

Model | XRC400 | XRC500 | XRC600 | XRC800 | XRC1000 | XRC1200 |

Rotating diameter(mm) | 220 | 280 | 320 | 450 | 450 | 580 |

Speed(rpm) | 550 | 550 | 600 | 600 | 600 | 600 |

Rotating knives(pcs) | 12 | 15 | 18 | 24 | 30 | 60 |

Fixed knives(pcs) | 2 | 2 | 4 | 4 | 4 | 4 |

Motor(kw) | 7.5 | 15 | 18.5-22 | 37-45 | 45-75 | 75-90 |

COOPERATION PARTNER