PP Woven Bag Washing Line

The PP woven bag recycling line is designed for processing various types of PP woven bags such as rice bags, cement bags, and more. The complete process includes shredding, water rinsing, friction washing, drying through the washing system, as well as compacting, plasticization, pelletizing, and drying through the pelletizing system. With over 20 years of experience in recycling, Gangsu has not only mastered the key technologies but also enhanced machine designs to cater to specific product characteristics.

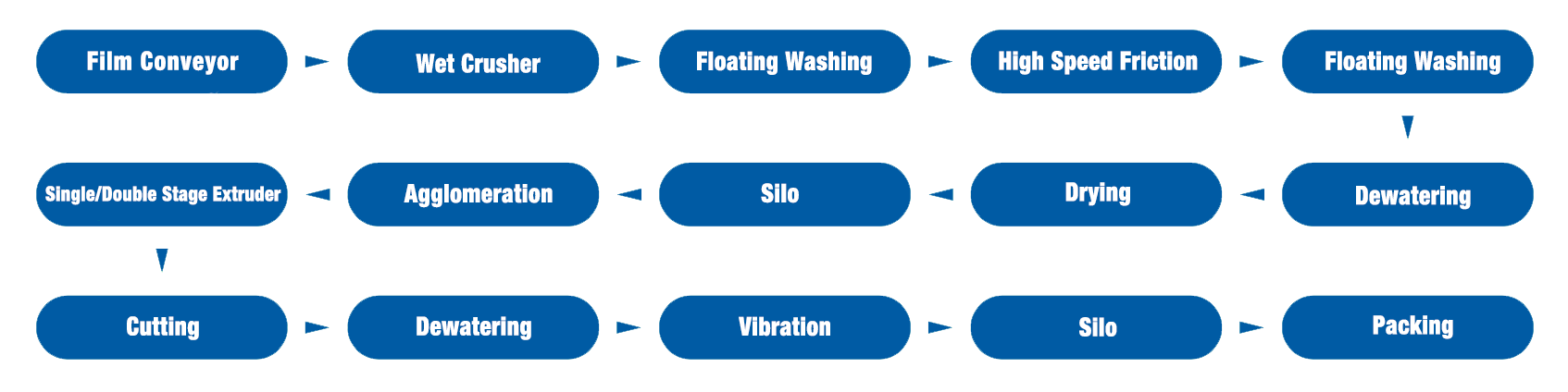

WORKING PROCESS

UNIT INTRODUCTION

Belt Conveyor

Used for conveying material, the surface of the belt is equipped with anti-slip devices and the height is adjustable.

Crusher

To crush the raw material into smaller pieces with water added during the process. The blade material is SK11.

Friction Washer

The high-speed rotating screw makes the material to be thoroughly scrubbed with water, effectively washing away its impurities.

Floating Washer

Used for separating sand, pulp, and other impurities from the raw materials. The main material used is stainless steel.

Dehydrator

High-speed centrifugal dehydration to remove moisture from the material and simultaneously eliminate residual impurities.

Squeezer

The material is squeezed and partially plasticizing through the screw compress, allowing for direct pelletizing with higher output.

Hot air dryer

For drying the material through hot air pipeline, which is also insulated with thermal insulation material to reduce energy consumption loss.

Control Cabinet

For control the operation of the entire line. Electrical components adopts famous brands such as ABB, Siemens, Omron, Schneider etc.

TECHNICAL DATA

Device parameters | ||||

| Model | Capacity | Motor Power | Equipment footprint | |

GSB-500 | 500kg/h | 150KW | 120m 2 | |

GSB-1000 | 1000kg/h | 190KW | 260m 2 | |

GSB-2000 | 2000kg/h | 290KW | 380m 2 | |

Unit energy consumption | ||||

Content | Average energy consumption per ton of bottle | |||

Electricity | 180-250KW | |||

Water | 1.5-3T | |||

Compressed air | 0.5-1m 3 | |||

Steam (optional) | 0-100KG | |||

Detergent (optional) | 0-5KG | |||

COOPERATION PARTNER