Rigid PP PE Washing Recycling System

Recycle Plastic Waste to Make Profit

Gangsu has consistently incorporated European and Chinese washing line technologies and continuously refined them. As a result, it has developed a range of modular equipment capable of accommodating the distinctive characteristics of HDPE/PP/PS/ABS/PC/PET materials. These equipment modules are designed for the recycling of blow-molded packaging bottles, boxes, cups, barrels, buckets, as well as injection waste. They enable the realization of a comprehensive cleaning and recycling line that can handle both rigid and flexible plastics. The modules encompass sorting, size reduction, metal removal, cold and hot washing, high-efficiency friction washing, and drying. They are highly effective in removing various contaminants, such as ferrous and non-ferrous metals, sand, oil, glue, paper, and other impurities.

APPLICABLE MATERIALS

BRIEF DESCRIPTION

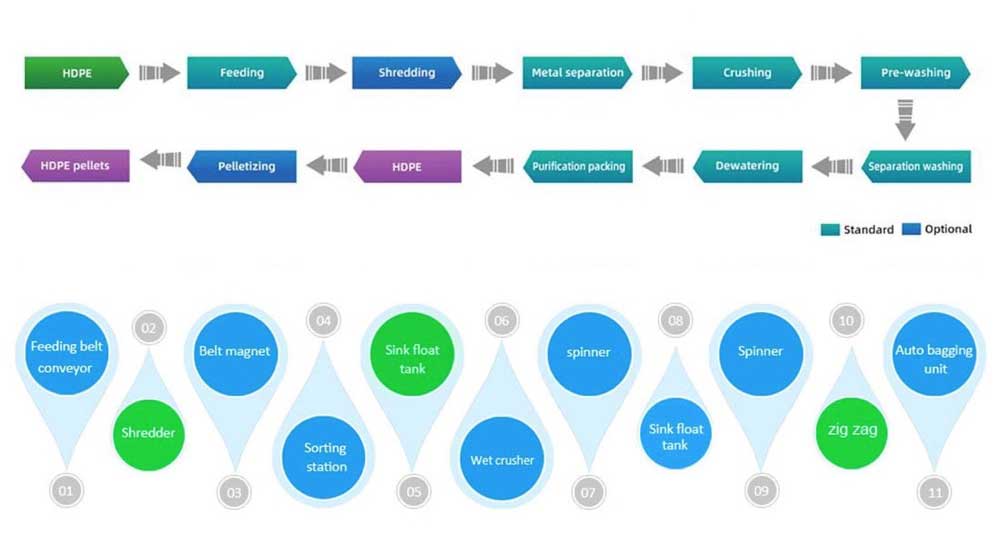

The HDPE washing recycling system is designed to process various types of HDPE waste plastics. The treated HDPE can be used for the production of plastic granules and plastic products.

HDPE plastics are primarily used in the manufacturing of various packaging materials, notably bottles and barrels.

Typically, large-sized HDPE materials require shredding before processing, while smaller-sized HDPE materials can be directly crushed.

The presence of different impurity residues varies depending on the application of HDPE materials in different settings. Accordingly, we can design and adjust the corresponding plant to accommodate these impurity residues.

Additionally, the HDPE washing recycling line is also suitable for recycling similar-sized PP materials.

WORKING PROCESS

UNIT INTRODUCTION

Belt Conveyor

Used for conveying material, the surface of the belt is equipped with anti-slip devices and the height is adjustable.

Crusher

To crush the raw material into smaller pieces with water added during the process. The blade material is SK11.

Friction Washer

The high-speed rotating screw makes the material to be thoroughly scrubbed with water, effectively washing away its impurities.

Floating Washer

Used for separating sand, pulp, and other impurities from the raw materials. The main material used is stainless steel.

Dehydrator

High-speed centrifugal dehydration to remove moisture from the material and simultaneously eliminate residual impurities.

Squeezer

The material is squeezed and partially plasticizing through the screw compress, allowing for direct pelletizing with higher output.

Hot air dryer

For drying the material through hot air pipeline, which is also insulated with thermal insulation material to reduce energy consumption loss.

Control Cabinet

For control the operation of the entire line. Electrical components adopts famous brands such as ABB, Siemens, Omron, Schneider etc.

TECHNICAL DATA

| Washing Process | ||||

| Belt conveyor | Belt width(mm) | 600 | 800 | 800 |

| Motor power(KW) | 2.2 | 3 | 3 | |

| Crusher | Grind chamber(mm) | 500*700 | 700*1000 | 700*1200 |

| Motor power(KW) | 55 | 75 | 90 | |

| Screw conveyor | Screw diameter(mm) | 250 | 300 | 400 |

| Friction washer | Screw diameter(mm) | 300 | 400 | 450 |

| Washing tank | Dimension of tank(mm) | 5000×1200 | 6000×1600 | 8000×1800 |

| Screw conveyor | Screw diameter(mm) | 250 | 300 | |

| Centrifugal dryer | Rotor diameter(mm) | 460 | 500 | 550 |

| Hot air pipe dryer | Pipe diameter(mm) | 133 | 159 | 169 |

| High-speed hot cleaning | ||||

| Color sorter | ||||

| Storage buffer | Storage capacity(CBM) | 3 | 4 | 6 |

COOPERATION PARTNER