LDPE/HDPE film bag pelletizing line

LDPE/HDPE film bags are a commonly recycled material, and our solution offers efficiency and environmental friendliness. It includes compacting, plasticization, pelletizing, and drying processes. With our PLC intelligent system, the line achieves high automation, requiring only 2-3 operators.

With over 20 years of experience in recycling, Gangsu has mastered the key technology and continuously improved machine designs to cater to specific product requirements. Our recycling solutions provide high output and low energy consumption.

Agricultural film mulch film water ring pelletizing line

APPLICABLE MATERIALS

BRIEF DESCRIPTION

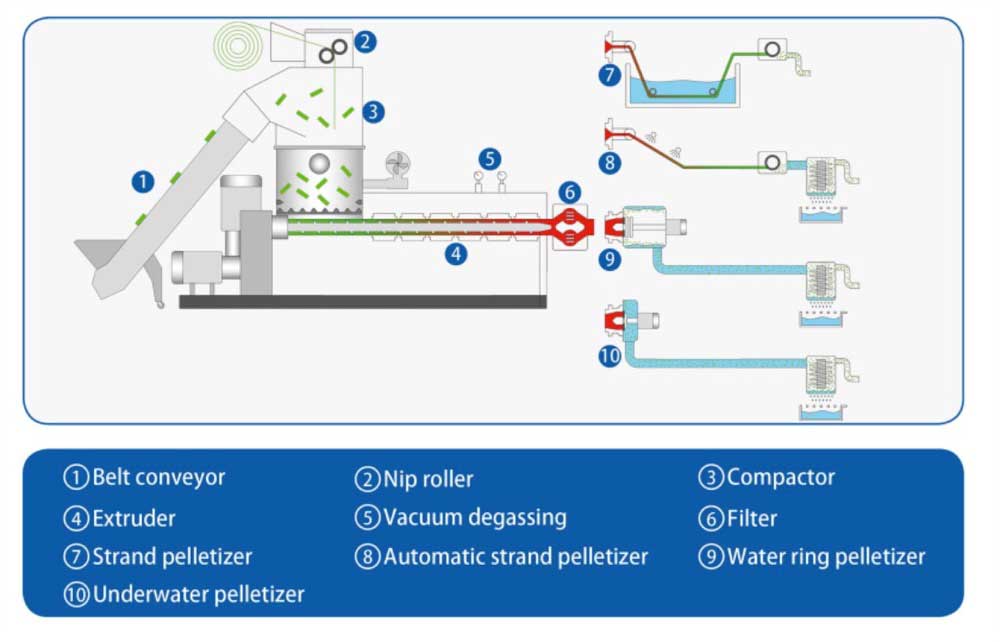

- Our plastic compacting and pelletizing system offers a comprehensive solution by combining the functions of crushing, compacting, plasticization, and pelletizing into a single step. It is specifically designed for plastics recycling and reprocessing.

- This system provides a reliable and efficient solution for re-pelletizing various plastic materials such as films, raffias, filaments, bags, woven bags, and foaming materials.

- The final products produced by our system are in the form of pellets or granules, which can be directly used in film blowing, pipe extrusion, plastics injection, and other production processes.

DETAILED PICTURES

WORKING PROCESS

UNIT INTRODUCTION

Compacting Force Feeder

Compacting hopper opening by hydraulic system. With glass window and light to check inside working. Barrel base with the water cooling system controlled by magnetic valve by temperature The barrel touched material all made by stainless steel.

Screw Extruder

Single Screw Extruder made by sturdy frame, heavy. No vibrating when machine running Use 38CrMoAL made the screw The whole frame where installed the gearbox, motor and screw has done the milling working. The frame is build up by the square tube and thick steel on top.

Hydraulic Screen Changer

Double position board model Board made by 38CrMnAl with forging, heating treatment won’t deform after heating using.

Vacuum Degassing Die Head

Remover the waste air, moisture for plastic before go to baby stage.

Noodle Die Head

Die mold made by the 40Cr material with forging treatment, surface been nitrided treatment and manufacturing by CNC.

Pelletizer Cutter

Pellet size: Φ3*3mm Noodle Number: 25PCS

Vibrator

By vibrator and screen choose different size granules.

Air Feeding System & Silo Storage

Collect plastic pellets.

TECHNICAL DATA

SJ series single stage pp pe film granulator machine | ||||||||||

Model | SJ-65 | SJ-80 | SJ-100 | SJ-120 | SJ-150 | SJ-200 | ||||

Screw Dia. | 65 | 80 | 100 | 120 | 150 | 200 | ||||

L/D | 28-30 | 28-30 | 28-30 | 28-30 | 28-30 | 28-30 | ||||

Capacity | 60-80kg/h | 80-100kg/h | 150kg/h | 300kg/h | 500kg/h | 800kg/h | ||||

SJ series double-stage pp pe film granulator machine | ||||||||||

Model | SJ-100/100 | SJ-120/120 | SJ-150/150 | SJ-200/200 | ||||||

Screw Dia. | 100 | 120 | 150 | 200 | ||||||

L/D | 28-30 10-15 | 28-30 10-15 | 28-30 10-15 | 28-30 10-15 | ||||||

Capacity | 120-180kg/h | 220-300kg/h | 400-500kg/h | 800-1000kg/h | ||||||

COOPERATION PARTNER