PET Bottle Washing Recycling System

PET bottle washing line is mainly used to recycle PET bottle flakes from old PET bottles for other post pelletizing processes. The PET pellets obtained after the SSP process can be directly contacted with the blow molding packaging of food.

APPLICABLE MATERIALS

TECHNICAL DATA

| Capacity(kg/h) | Power(kw) | Size(m²) | Staff | Qty of steam(kg/h) | Compressed air(m³/min) | Water(m³/h) |

| 500 | 220 | 400 | 8 | 350 | 4 | 1 |

| 1000 | 500 | 750 | 10 | 500 | 10 | 3 |

| 2000 | 700 | 1000 | 12 | 800 | 15 | 5 |

| 3000 | 900 | 1500 | 12 | 1000 | 15 | 6 |

| 4500 | 1000 | 2200 | 16 | 1300 | 18 | 8 |

| 6000 | 1200 | 2500 | 16 | 1800 | 18 | 10 |

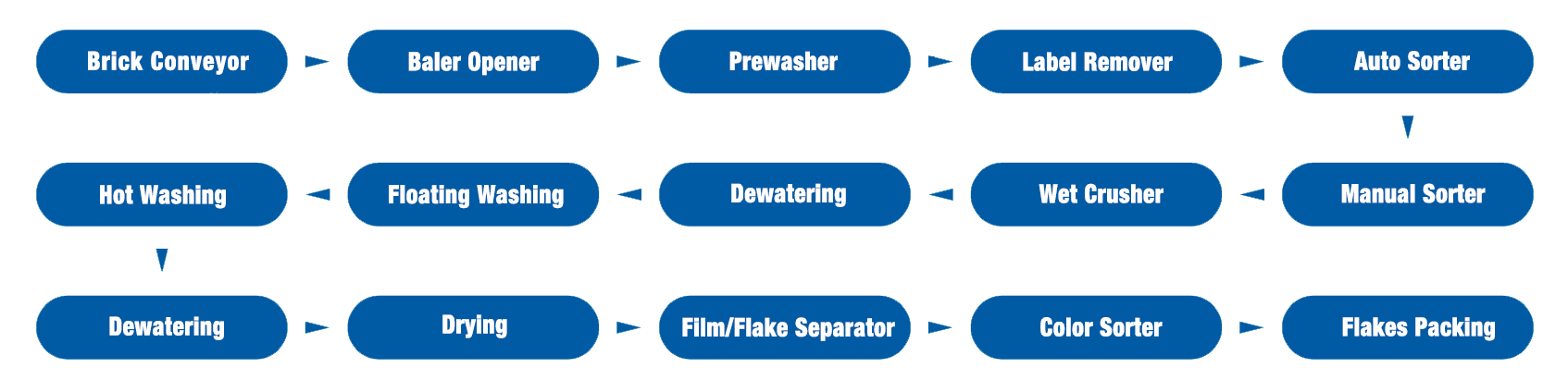

WORKING PROCESS

UNIT INTRODUCTION

Label Remover

For removing the label paper on PET bottles ,while the attached dirt and sediment are subjected to preliminary rinsing.

Crusher

To crush the raw material into smaller pieces with water added during the process. The blade material is SK11.

Friction Washer

The high-speed rotating screw makes the material to be thoroughly scrubbed with water, effectively washing away its impurities.

Washing tank

Used for separating sand, pulp, and other impurities from the raw materials. The main material used is stainless steel.

Hot Washer

Core of the PET washing line, for removing stubborn contaminants such as adhesive, oil, residue, and liquid for higher-quality PET flakes.

Hot Air Dryer

For drying the material through hot air pipeline, which is also insulated with thermal insulation material to reduce energy consumption loss.

Label Seperator

The label and other impurities like dust can be separated by blowing air with the principle of gravity separation.

Control Cabinet

For control the operation of the entire line. Electrical components adopts famous brands such as ABB, Siemens, Omron, Schneider etc.

2000kg/hr PET bottle washing line (Gangsu)

Turnkey Project Delivery Case

- Material: PET Bottle Waste

- Output Capacity: 500KG/H

- Floor Space: 350m²

- Installation Power:315KW

- Water Consumption: 7 m²/H

COOPERATION PARTNER